|

|

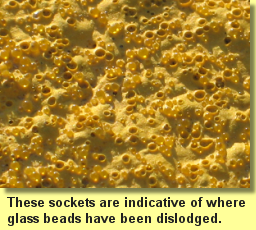

Got Sockets?By Mike Speidel

When Sightline technicians are on the ground looking through a magnifying glass observing bead embedment, among other things, we often see sockets or craters where glass beads once resided. Despite the graphic, right, we do not split up into search parties in an effort to find missing glass beads. Instead we record the bead embedment as being poor on that marking, most likely due to inadequate material coverage. When the application is poor at the outset, sockets are a common result, and the markings become ineffective soon after installation. More maintenance will be needed sooner, and so the process repeats! To put it simply, the material coverage rates for the binder, typically waterborne paint, must be sufficient and suitable for the reflective media being applied. Type 4 bead users pay attention: The Type 4 low-index bead is nearly twice the size of both the Type 1 and Type 3 glass

beads. Proper bead embedment is acheived when 50-60% of the glass spheres are submerged in the coating. The

original standard specification of 115 ft2/gal for waterborne paint works for Type 1 and Type 3

beads - not for the Type 4! Applying Type 4 beads into a wet coating applied at 115 ft2/gal

results in lots and lots of sockets in a couple weeks of traffic! Instead, use waterborne specification

TT-P-1952E-Type III, a high-build acrylic, with the Type 4 bead. It's applied at a greater rate

(e.g. 60 ft2/gal) providing a thicker wet film to satisfy the bigger Type 4 bead. I don't

recommend the use of Type 4 glass beads on airfields, but if you must, the high-build acrylic must be married

with the larger beads.

The Type 4 low-index bead is nearly twice the size of both the Type 1 and Type 3 glass

beads. Proper bead embedment is acheived when 50-60% of the glass spheres are submerged in the coating. The

original standard specification of 115 ft2/gal for waterborne paint works for Type 1 and Type 3

beads - not for the Type 4! Applying Type 4 beads into a wet coating applied at 115 ft2/gal

results in lots and lots of sockets in a couple weeks of traffic! Instead, use waterborne specification

TT-P-1952E-Type III, a high-build acrylic, with the Type 4 bead. It's applied at a greater rate

(e.g. 60 ft2/gal) providing a thicker wet film to satisfy the bigger Type 4 bead. I don't

recommend the use of Type 4 glass beads on airfields, but if you must, the high-build acrylic must be married

with the larger beads.

What you need for proper embedment:

Paying attention to the details is what makes markings effective - and they will last! Shameless promotion alert: Sightline specializes in the details of airfield markings - our expertise will save you headaches and valuable project funds! Contact us, we will be gentle. |

Material coverage rates for waterborne paint and glass beads are specified in every

airfield marking project. The FAA's guidance literature

(

Material coverage rates for waterborne paint and glass beads are specified in every

airfield marking project. The FAA's guidance literature

(