|

|

Airfield Marking Handbook - Chapter 3By Mike Speidel

This piece is the second in a six article series summarizing each chapter contained within the Handbook. As the principal authors of the Airfield Marking Handbook, we will also be identifying key issues for your consideration.

Materials Chapter 3 addresses the material used for airfield markings. This includes different types of both binders and glass beads. In addition, information about the performance and compatibility of various material combinations is provided. Choices of binders include water-borne (Type I, II, or III), solvent-borne, epoxy, and methyl methacrylate. Choices of glass beads include TT-B-1325, Type I, III or IV. Many different marking materials are used for airfield markings. At the simplest level, airfield markings consist of a combination of a binder and glass beads. Selecting the right materials for the job is important. The airport environment, amount of traffic, safety issues, schedules of operations, types of pavement, and existing marking materials should be considered when determining which materials to use. Choosing the optimal materials may increase initial costs, but over the long term this should be more cost effective; and, it can provide an added measure of safety.

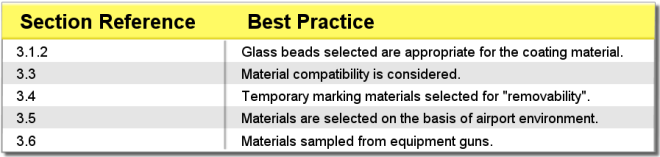

This chapter affects the design engineers, applicators, and inspectors most directly. Having the correct materials for the job in question is only half of the solution; knowing how to derive value from those materials utilizing the best practices is how to achieve optimal results. If the engineer specifies suitable materials, the applicators utilize appropriate equipment and techniques, and the inspection personnel provide sound quality assurance, the markings will reflect it. Have not these criteria, and the markings will reflect that as well. The Materials section discusses the physical properties of waterborne paints and glass beads. Being aware of potential compatability problems between materials can save a lot of time and money. Waterborne paints should not be installed over existing oil based material, for example. The use of Type IV beads should be limited to a marriage with a high-build coating: we wrote an article about that pitfall in the Summer of '07. Being knowledgable of the issues is nice; yet one has to apply the knowledge to prevent potential problems and liability for the airport. It turns out being materialistic isn't such a bad thing after all! Also discussed in Chapter 3:

Want a handbook? Check this out. If you'd like a free handbook, and to join Sightline to discuss the manual, may I suggest you take a look at this: Airfield Marking Symposium, May 17th in Atlanta, GA. |

With the Airfield Marking Handbook hot off the presses and now being distributed to the industry, let's take a look at

what's inside. In each of the next several issues of Sightline's webletter, I'm going to take a look at each chapter and it's

highlights. It's the most comprehensive resource available dealing strictly with airfield markings. To obtain a copy,

With the Airfield Marking Handbook hot off the presses and now being distributed to the industry, let's take a look at

what's inside. In each of the next several issues of Sightline's webletter, I'm going to take a look at each chapter and it's

highlights. It's the most comprehensive resource available dealing strictly with airfield markings. To obtain a copy,