|

|

Airfield Marking Handbook - Chapter 7By Mike Speidel

Inspection Techniques This chapter in the AMH discusses inspection techniques employed before, during, and after application to ensure a quality marking project. The material contained in this chapter is of greatest benefit to project inspectors, and would be useful to applicators as they monitor their own work.

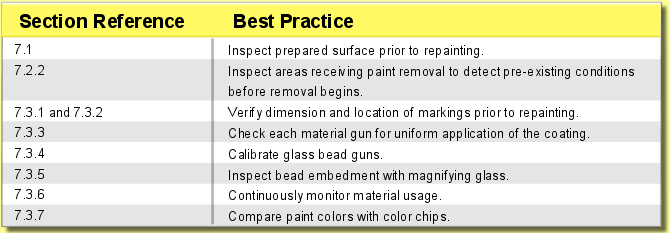

Chapter 7 discusses the best practices for visual inspection when monitoring airfield markings. Inspection of performed surface preparation, paint removal, marking layout dimension and location, material coverage rates, and bead embedment are all identified as items on the inspector's checklist. Inspection is the last of the steps in the marking system to ensure the end product is of high quality. As Chapter 4 in the AMH states, the surface to be painted must be clean and free of loose materials to ensure a proper bond between coating and pavement. It is a best practice for the inspector to verify the surface is clean of any contaminants prior to painting. 75% of all coating failures are attributable to deficient surface preparation and/or application. If the inspector demands clean surface conditions upon application it improves the life cycle of the marking system. When paint removal is required on a project, inspectors must be aware of the degree of removal to be achieved as well as the pavement scarring associated with the removal. It is a best practice to evaluate the paint removal operation in a test area first in order to establish expectations of the equipment and the operator. If markings are obsolete, they should be removed to a 95-100% degree. If the markings are to be repainted in the same location and the existing material is compatible, then 85% removal is acceptable. The inspector is responsible for verifying the specified degree of removal and any scarring is acceptable. Inspection also includes making certain the markings are laid out in the proper location and dimension. Once the painting begins, specified coverage rates should be monitored to ensure proper coating thickness and bead population, distribution, and embedment. An inspector should always have a magnifying glass on hand to make certain these factors are satisfactory during application. Adjustments can be made during the application to achieve desired results in the case of an unsatisfactory product. Want a handbook? Check this out. If you'd like a free handbook, be sure to attend one of our Airfield Marking Symposiums in 2010. Locations have recently been released! |

With the Airfield Marking Handbook hot off the presses and now being distributed to the industry, let's take a look at

what's inside. It's the most comprehensive resource available dealing strictly with airfield markings. This is the final segment in the

six-article series summarizing the Airfield Marking Handbook. As the principal authors of the Airfield Marking Handbook, we will be

identifying key issues for your consideration. To obtain a copy,

With the Airfield Marking Handbook hot off the presses and now being distributed to the industry, let's take a look at

what's inside. It's the most comprehensive resource available dealing strictly with airfield markings. This is the final segment in the

six-article series summarizing the Airfield Marking Handbook. As the principal authors of the Airfield Marking Handbook, we will be

identifying key issues for your consideration. To obtain a copy,