|

|

Dispensing KnowledgeBy Donna Speidel

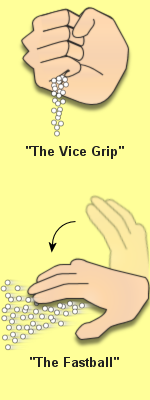

We've seen a lot of bead dispensers on shelves, in drawers, or laying in corners at airports around the country. Walk-behind airless paint machines were designed originally for parking lot striping, and beads are seldom needed there; so glass bead dispensers were an afterthought when sold to airports. The dispensers that are standard on the airless machines don't always work very well; they tend to become fouled easily, and a lot of maintenance is required. Thus, to "comply" with adding glass beads to markings that are required to be reflective, many airport personnel and contractors resort to hand-throwing the beads. Many styles have been invented over the last fifteen years, some of my favorites are illustrated on the right! The result of hand-throwing is the beads are not distributed evenly and do not embed well in the coating. The markings are poorly applied and in a short time, become ineffective and difficult to see during darkness when pavement markings are needed most.

FAA Advisory Circulars 150/5370-10E, P620-3.5 and 150/5340-1K state: "glass beads shall be distributed upon the marked areas at the locations shown on the plans to receive glass beads immediately after application of the paint. A dispenser shall be furnished which is properly designed for attachment to the marking machine and suitable for dispensing glass beads." Seeing the glaring need for "properly designed" equipment, Sightline has developed a suitable glass bead dispensing system that actually works! In fact, we recently received a patent for the RoboBeader®. The RoboBeader can be added to new machines or retrofitted to accommodate machines currently in service. It can be calibrated to apply the correct amount of glass beads onto a six-inch marking. If a wider marking is being applied, multiple glass bead dispensers will be needed to adequately reflectorize the marking. The advantages to the RoboBeader system:

To order a RoboBeader, call (540) 825-9660, and ask for Morgan (ext. 2), or email us. To see a RoboBeader demo, attend an Airfield Marking Symposium. |

"I know what you're thinking," the striping machine operator said to me, "I shouldn't be

hand-throwing the glass beads. But the bead dispenser doesn't work, and it's back at the shop on the shelf."

"I know what you're thinking," the striping machine operator said to me, "I shouldn't be

hand-throwing the glass beads. But the bead dispenser doesn't work, and it's back at the shop on the shelf."