|

Back to Webletter

Reading Between The Lines

By Donna Speidel

As this is our summer edition, it may be a bit premature to talk about snow and ice on airfields, especially since many

of us have had a hot, dry summer! But it is September, after all; fall is upon us, and for some in the northern climates, snow

isn't far away.

Clever designers devised striated markings as a way to alleviate the problem of ice and snow lingering on large, white

airfield markings. By applying the marking with a series of lines ranging from 4 inches (10 cm) to 8 inches (20 cm), the space in between

exposes the darker asphalt to the sun, and melts the snow and ice on the markings more quickly. However,

|

"Since striated markings have a reduced visibility, more frequent maintenance is required to provide an acceptable marking system.

Striated markings are not used on Category II and Category III precision runways." (FAA AC 150/5340-1J)

|

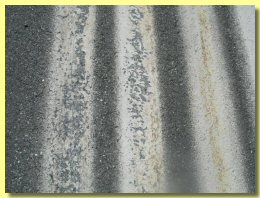

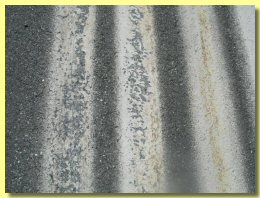

"More frequent maintenance" to most airports means repainting more often, resulting in paint build up. For

striated markings, this means that ridges of paint build up and present a higher profile than the unpainted area, making it susceptible to

being scraped off during snowplow operations and heavy brooming (see picture), resulting in a loss of paint, glass beads, and safety until yet

more paint can be applied during warmer months. For some, that can result in more than six months without a safe airfield marking system; an

issue that is becoming more and more visible.

"More frequent maintenance" to most airports means repainting more often, resulting in paint build up. For

striated markings, this means that ridges of paint build up and present a higher profile than the unpainted area, making it susceptible to

being scraped off during snowplow operations and heavy brooming (see picture), resulting in a loss of paint, glass beads, and safety until yet

more paint can be applied during warmer months. For some, that can result in more than six months without a safe airfield marking system; an

issue that is becoming more and more visible.

Repeated painting of the striations often leads to "solid" markings when the stripes miss the mark, negating benefit of the

striations. And it appears that the narrower the striation, the less visible the markings are. Erratic repainting can also create a very difficult

scenario in a removal effort. With varying coverage in paint, specifying a removal project and physically performing the removal would be a

challenge.

"More frequent maintenance" should include:

- Surface preparation or removal of the striations to prevent the build up, to keep the profile down and less prone to removal with snowplowing operations; and

- Due to the smaller painted area, a higher indexed glass bead (TT-B-1325D, Type III) may be advisable due to reduced visibility.

Back to Webletter

|

"More frequent maintenance" to most airports means repainting more often, resulting in paint build up. For

striated markings, this means that ridges of paint build up and present a higher profile than the unpainted area, making it susceptible to

being scraped off during snowplow operations and heavy brooming (see picture), resulting in a loss of paint, glass beads, and safety until yet

more paint can be applied during warmer months. For some, that can result in more than six months without a safe airfield marking system; an

issue that is becoming more and more visible.

"More frequent maintenance" to most airports means repainting more often, resulting in paint build up. For

striated markings, this means that ridges of paint build up and present a higher profile than the unpainted area, making it susceptible to

being scraped off during snowplow operations and heavy brooming (see picture), resulting in a loss of paint, glass beads, and safety until yet

more paint can be applied during warmer months. For some, that can result in more than six months without a safe airfield marking system; an

issue that is becoming more and more visible.