|

Back to Webletter

Be Prepared

By Donna Speidel

A REPAINT PRO. It's an anagram, meaning another word can be made by rearranging the letters in

a different sequence. The word I'm thinking of is PREPARATION. Being prepared is paramount if a repaint operation is to

be successful. In fact, surface prepartion and layout are 90% of a job well done. Without them, paint failures and error

are likely realized. But today, I'm focusing on another big issue that paint build-up can lead to... premature pavement

deterioration.

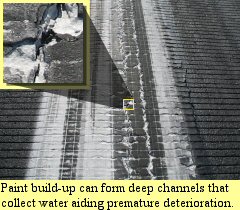

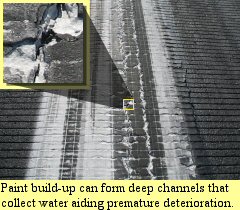

This centerline marking is showing evidence of asphalt cracking. Layering more paint only worsens the

problem, as the paint build up turns into channels for water to penetrate, getting under the paint to attack the

underlying asphalt. Over time, the asphalt rots from the moisture being trapped between paint and pavement. Where the

painted markings are, you will often find the asphalt deteriorating; and relative to the adjacent pavement, the marked

asphalt will be aging prematurely. We believe this can be avoided by regularly cleaning the markings prior to a new

application of paint using high pressure water blasting (up to about 10,000 psi at 20-25 gpm.)

This centerline marking is showing evidence of asphalt cracking. Layering more paint only worsens the

problem, as the paint build up turns into channels for water to penetrate, getting under the paint to attack the

underlying asphalt. Over time, the asphalt rots from the moisture being trapped between paint and pavement. Where the

painted markings are, you will often find the asphalt deteriorating; and relative to the adjacent pavement, the marked

asphalt will be aging prematurely. We believe this can be avoided by regularly cleaning the markings prior to a new

application of paint using high pressure water blasting (up to about 10,000 psi at 20-25 gpm.)

The old paint on this threshold marking looks like it could be painted over, but look what water blasting

at just 8,000 psi does.

The old paint, though it may look tight, is brittle from months or years of UV degradation, water erosion,

freeze/thaw cycles, and general drying out of polymers in the paint as it ages. Painting over the brittle paint particles

may be okay for a while; but eventually, the layers of paint begin to crack and the picture at the top of this page begins

to take shape. It is a gradual process and happens more quickly with more frequent painting cycles. Asphalt is

particularly susceptible; on concrete, the paint tends to build up and then loosen in larger chunks. This constitutes FOD.

Prepare your pavements = Protect your pavements.

The old paint, though it may look tight, is brittle from months or years of UV degradation, water erosion,

freeze/thaw cycles, and general drying out of polymers in the paint as it ages. Painting over the brittle paint particles

may be okay for a while; but eventually, the layers of paint begin to crack and the picture at the top of this page begins

to take shape. It is a gradual process and happens more quickly with more frequent painting cycles. Asphalt is

particularly susceptible; on concrete, the paint tends to build up and then loosen in larger chunks. This constitutes FOD.

Prepare your pavements = Protect your pavements.

We have a resource at cleanrunways.com

that lends a hand with writing project specifications. These specs are more rigorous than most, and need to be in order

to achieve a higher standard. Surface preparation is currently listed as 85% marking removal, however will soon have a

seperate set of specs written exclusively for it.

Back to Webletter

|

This centerline marking is showing evidence of asphalt cracking. Layering more paint only worsens the

problem, as the paint build up turns into channels for water to penetrate, getting under the paint to attack the

underlying asphalt. Over time, the asphalt rots from the moisture being trapped between paint and pavement. Where the

painted markings are, you will often find the asphalt deteriorating; and relative to the adjacent pavement, the marked

asphalt will be aging prematurely. We believe this can be avoided by regularly cleaning the markings prior to a new

application of paint using high pressure water blasting (up to about 10,000 psi at 20-25 gpm.)

This centerline marking is showing evidence of asphalt cracking. Layering more paint only worsens the

problem, as the paint build up turns into channels for water to penetrate, getting under the paint to attack the

underlying asphalt. Over time, the asphalt rots from the moisture being trapped between paint and pavement. Where the

painted markings are, you will often find the asphalt deteriorating; and relative to the adjacent pavement, the marked

asphalt will be aging prematurely. We believe this can be avoided by regularly cleaning the markings prior to a new

application of paint using high pressure water blasting (up to about 10,000 psi at 20-25 gpm.)

The old paint, though it may look tight, is brittle from months or years of UV degradation, water erosion,

freeze/thaw cycles, and general drying out of polymers in the paint as it ages. Painting over the brittle paint particles

may be okay for a while; but eventually, the layers of paint begin to crack and the picture at the top of this page begins

to take shape. It is a gradual process and happens more quickly with more frequent painting cycles. Asphalt is

particularly susceptible; on concrete, the paint tends to build up and then loosen in larger chunks. This constitutes FOD.

Prepare your pavements = Protect your pavements.

The old paint, though it may look tight, is brittle from months or years of UV degradation, water erosion,

freeze/thaw cycles, and general drying out of polymers in the paint as it ages. Painting over the brittle paint particles

may be okay for a while; but eventually, the layers of paint begin to crack and the picture at the top of this page begins

to take shape. It is a gradual process and happens more quickly with more frequent painting cycles. Asphalt is

particularly susceptible; on concrete, the paint tends to build up and then loosen in larger chunks. This constitutes FOD.

Prepare your pavements = Protect your pavements.